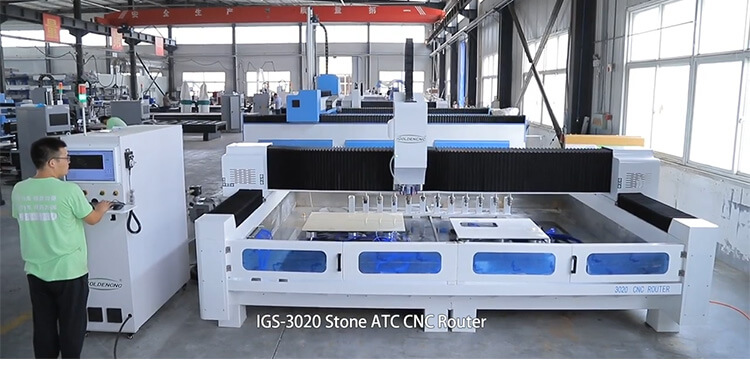

Quartz stone CNC Machining Center

CNC stone machining center-quartz stone cabinet countertops processing, stone side modeling, arc retaining water grinding, basin pots, stone relief, hollow, line carving. Granite, marble, bluestone, tombstone, headstone and other stone materials processing. One-key intelligent completion of conventional blanking, 45° bevel cutting, multi-angle arbitrary cutting, curve cutting, internal angle and basin hole cutting and other processes.Now, the affordable CNC stone machining machine is sold at the best price.

CNC Stone Machining Center Video

Quartz Stone CNC Processing Center Applications

Technical Data

| X, Y Axis Working Area | 2000*3000mm |

| Z Axis Working Height | 500mm |

| Positioning Accuracy | 0.05mm |

| Re-positioning Accuracy | 0.02mm |

| Body Structure | Welding Body |

| X, Y Axis Structure | Gear Rack |

| Z Axis Structure | Screw |

| Max. Running Speed | 20000mm/min |

| Max. Working Speed | 10000mm/min |

| Spindle | 5.5kwWater-cooling |

| Spindle RPM | 24000 |

| Working Voltage |

AC 380V±10% /50-60Hz |

| Machine Weight | 3300kg |

If you need more detailed information, please inform us as soon as possible.

CNC Stone Machining Center Description

CNC stone cutting & polishing machine 3020 is used for cabinets artificial stone, quartz stone, granite, marble carving, cutting, polishing, drilling, engraving. Now the affordable CNC stone machine for sale at cost price.

12 Linear Tools Magazine

CNC Stone Machining Center With Linear ATC Positions for stone cutting, profiling, Edging, milling,

5.5kw Water-cooled Spindle

Dustproof and waterproof sealed, the body is smooth and not easy to rust, and the rotation accuracy is high. The bearing has long life, high speed and low noise, stable operation, no chipping in machining, high spindle accuracy and maintenance-free.

Upgraded Intelligent Control System

NC65 Series Controller Faster Responsible & Strong Function Inset CAM/CAD design software

Stone CNC Machine Center Application:

The advanced CNC stone machining center designed by iGOLDENCNC adopts a high-strength mechanical structure, which is very suitable for manufacturers of kitchen cabinets and bathroom supplies processing industries. It adopts imported linear guide rails to ensure accuracy and provides a set of competitive configurations.

1.Stoneworks: 3D/2D stone carving, Embossment, Line engraving Cutting, Edge inversing, Drilling on Natural stones, Granites, Artifical stones, Tombstones, Milestones, Ceramic, etc.

2.Die industry: Copper sculpture,aluminum engrave,metal molds,plastic sheeting,PVC ,etc

3. Heavy Cut Machine for Pyramid Type Stone

4. It is widely used in the gemstones production.

Contact Us Today to Get Price!

Stone CNC machining center is a special kind of stone CNC machine. The CNC stone machining center is a fully automatic stone CNC machinery designed for deep processing of quartz stone countertops, marble countertops, granite stone countertops, artificial stone countertops, slate countertops, and other stone countertops. Because the stone CNC machining can be divided into granite stone CNC machining, marble stone CNC machining, quartz stone CNC machining, jade stone CNC machining, crystal stone CNC machining, etc.

Sometimes stone CNC machining center is also called CNC stone cutting machine, CNC machine stone center, CNC machine for stone cutting, stone work machine, or CNC machine for stone and marble. Besides, this stone CNC machine can also realize drilling, milling, grinding, and cutting functions. Stone CNC working center can realize several different processes. For example, this CNC machine for stone can realize circular arc water-blocking grinding and polishing, table basin opening edging, Roman edge grinding and polishing, cutting of special-shaped plates, and processing of drain tank. Stone CNC machining center has many advantages, such as complete functions, environmental protection, high intelligence, and simple operation.

Stone CNC processing center is widely used in the processing of various panels such as kitchen countertops, bathroom countertops, island counters, bar counters, coffee tables, welcome counters, etc. The main materials processed by the quartz stone CNC center are quartz stone, marble, granite stone, artificial stone, slate, and other stones.

The scope of application of quartz stone machining centers are kitchen cabinet countertops, stone coffee table desktops, cutting of basin holes, bar counters, bathroom countertops, background wall carving, etc. The main uses of CNC processing stone center are front roman side processing, rear water-retaining round bottom processing, basin hole cutting processing, special-shaped cutting, and polishing.

- Fast speed, high precision, strong stability, low noise, and long service life.

- Automatic leveling function: It can correct the concave, convex and uneven slope of any stone surface. The software automatically generates a new program based on the floating of the stone surface, which conforms to the surface characteristics of the stone.

- Stable bed structure: The bed adopts high-quality steel structure and double beam design, and the gantry and work surface are respectively supported by reinforced beams. Therefore, it has the advantages of bearing load, no deformation, and high stability.

- Super cutting ability: Adopting high-power drive system coordinated with the spindle’s stable engraving, it has the features of greater torque force, smoother operation, precise and powerful cutting point. And Y-axis uses dual motor synchronous drive, it has the features of strong power, high stability, and can realize the process of 70mm Granite thickness.

- Longer service life: Use stainless steel sink, protection plate and other parts to fully protect the transmission parts and electrical components, so that the machine has a long service life.

- Advanced professional control system: It can be compatible with Type3 / Artcam / Castmate / pro-e / Ug / Cad / IIIustrator / Wentai / Jingdiao and other software.

- The working table of the marble engraving machine is a T-shaped steel bracket, using a full welding process and vibration aging treatment. Thus it can ensure the stable performance when the machine running at high speed, and continuous knife, keep the production processing surface is highly smooth.

- The CNC router stone engraving machine uses a high-power horizontal torque spindle, with large bearings. and with high speed, a large number of chips, and the motor is not easy to damage.

- Stone CNC routers are widely used in the Stone industry, stone tablet processing industry, art relief, advertising, decoration and decoration industry, ceramic industry.

- Perfect for Stone lettering, stone relief, stone yang carving, stone edging, stone line carving, stone cutting, stone hollowing.

his kind of stone countertop CNC machining center adopts an automatic tool change system (ATC processing system) and an automatic water circulating system. So that it can achieve a great processing effect without manual participation in the processing. Therefore, the ATC stone machining center has more outstanding automation. And the entire stone processing is completely conducted by the preset instructions for grinding, polishing, drilling, milling, and other actions. Then the seamless intelligent processing can be realized and the labor is better liberated. This kind of CNC quartz stone machining center is designed to solve the problems, such as time-consuming, labor-intensive, and high-cost in the production of stone countertops. At present, such kind of CNC stone center has a wide application in the processing of various stone countertops such as kitchen countertops, bathroom countertops, bar counter, coffee tabletops, stone tabletops, TV countertops, etc.

1.Wide Application

It can realize the functions of roman edge, rear-arc water retaining, upper middle and lower basin, special-shaped cutting, and grinding.

2.Environmental Protection

The whole process is automatic and environmentally friendly. And this kind of stone CNC grinding center for sale also builds a dust-free workshop that rejects pneumoconiosis.

3.Simple Operation

It’s easy to learn that even ordinary workers can get started in only one working day. It means that you will be more worry-free if using this kind of stone CNC machining center.

4.High Automation

This kind of ATC stone CNC machining center adopts an automatic tool change system and an automatic water-circulating system. It will be easy to achieve a great processing effect without manual participation in the processing.

Production Workshop