A Stone CNC Machine Center is a specialized tool used in the stone fabrication industry for cutting, shaping, and carving stone materials such as granite, marble, and other natural or engineered stones. These machines are designed to be highly precise and efficient, automating the process of creating intricate stone designs for various applications, including countertops, sculptures, monuments, and architectural elements.

Granite Countertop CNC Machine Features

Precision and accuracy: The machine is equipped with advanced computer software and precision tools that enable it to cut and shape stone materials with a high degree of accuracy and precision.

Complex designs and shapes: The machine’s advanced software and tooling enable it to create complex designs and shapes with ease, which would be difficult or impossible to produce with traditional stone fabrication methods. Edging and engraving function can be switched in one-key operation, which is easy to operate and correspondingly improve processing efficiency.

Reduced waste: The Stone CNC Machining Center can optimize material usage, reducing waste and saving money.

Increased production capacity: The machine’s versatility and improved efficiency enable it to handle larger and more complex projects, increasing production capacity and generating more revenue.

Functions of CNC Stone Machine Center

- Stone Cutting: Stone CNC machine centers are equipped with powerful spindles that can rotate cutting tools such as diamond-tipped router bits and saw blades. These cutting tools are used to cut through stone materials, such as granite, marble, quartz, and other natural or engineered stones. The machine can perform precise cuts for various shapes, edges, and cutouts required for kitchen cabinets and countertops.

- Engraving and Carving: Stone CNC machine centers have the ability to engrave intricate designs, patterns, and decorative elements onto stone surfaces. By utilizing specialized engraving tools and CNC control, the machine can create detailed carvings, lettering, and textures on the stone, adding aesthetic value to kitchen cabinets and other stone applications.

- CNC Control System: The machine is controlled by a CNC system, which allows for precise control of the cutting and engraving operations. The CNC control system interprets design files and generates tool paths to guide the machine’s movements. It ensures accuracy, repeatability, and consistency in the cutting and carving processes.

- Working Area and Bed Size: Stone CNC machine centers come in various sizes, with different working areas and bed sizes to accommodate different stone sizes and project requirements. It’s important to consider the size of the stone slabs or pieces you’ll be working with and ensure that the machine’s working area is suitable for your needs.

- Dust and Water Management: Stone cutting and engraving produce stone dust and debris, which can be harmful and messy if not properly managed. Stone CNC machine centers often include dust collection and water cooling systems. The dust collection system helps remove stone particles from the work area, while the water cooling system helps control heat generated during cutting and keeps the cutting tools and stone surfaces cool.

- Software Compatibility: Stone CNC machine centers are typically compatible with CAD/CAM software programs. This compatibility allows for the import of design files, such as DXF or STL, and the generation of tool paths for cutting, engraving, and carving operations. The software integration enables efficient programming and precise execution of design specifications.

- Safety Considerations: Stone CNC machine centers require appropriate safety measures to protect operators and ensure safe operation. These may include safety enclosures, emergency stop buttons, and proper training on machine operation and maintenance.

Granite Cnc Machine Application

A stone machining center is designed for the deep processing of quartz, marble, granite, slate, and other artificial stones. It can cut and drill holes, engrave letters and patterns, and mill and grind the stone surfaces. It is widely used to make kitchen countertops, bathroom washbasins, bar counters, coffee tables, stone statues and sculptures, tombstones and gravestones, and other artificial stone crafts and artworks.

IGOLDENCNC is a prominent China manufacturer of stone CNC machines, known for their high-quality and innovative solutions for stone processing. They offer a range of CNC machines for cutting, shaping, and polishing stone materials.

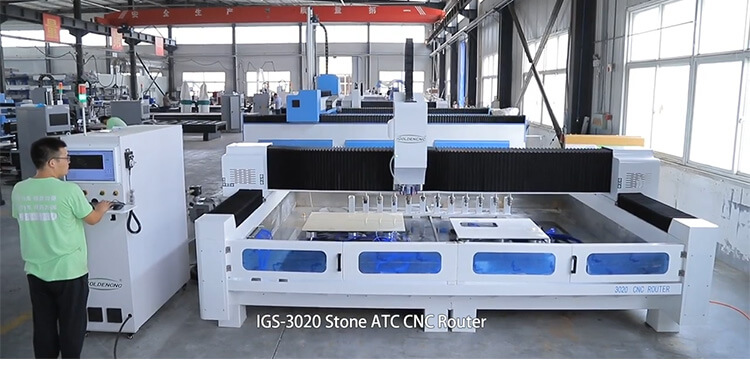

Quartz Stone CNC Machining Center with Automatic Tool Changer

This kind of stone countertop CNC machining center adopts an automatic tool change system (ATC processing system) and an automatic water circulating system. So that it can achieve a great processing effect without manual participation in the processing. Therefore, the ATC stone machining center has more outstanding automation. And the entire stone processing is completely conducted by the preset instructions for grinding, polishing, drilling, milling, and other actions. Then the seamless intelligent processing can be realized and the labor is better liberated. This kind of CNC quartz stone machining center is designed to solve the problems, such as time-consuming, labor-intensive, and high-cost in the production of stone countertops. At present, such kind of CNC stone center has a wide application in the processing of various stone countertops such as kitchen countertops, bathroom countertops, bar counter, coffee tabletops, stone tabletops, TV countertops, etc.

1.Wide Application It can realize the functions of roman edge, rear-arc water retaining, upper middle and lower basin, special-shaped cutting, and grinding.

2.Environmental Protection The whole process is automatic and environmentally friendly. And this kind of stone CNC grinding center for sale also builds a dust-free workshop that rejects pneumoconiosis.

3.Simple Operation It’s easy to learn that even ordinary workers can get started in only one working day. It means that you will be more worry-free if using this kind of stone CNC machining center.

4.High Automation This kind of ATC stone CNC machining center adopts an automatic tool change system and an automatic water-circulating system. It will be easy to achieve a great processing effect without manual participation in the processing.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.