Sliding Table Saw Uses and characteristics

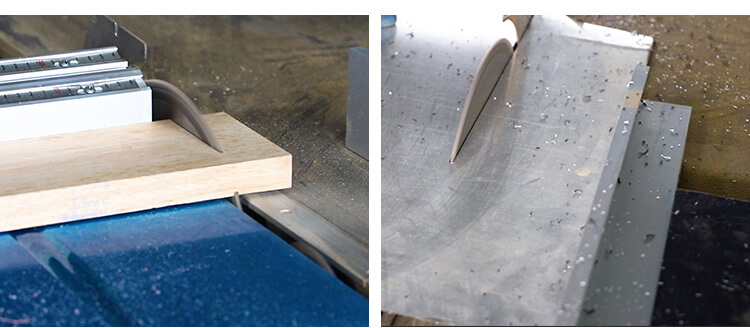

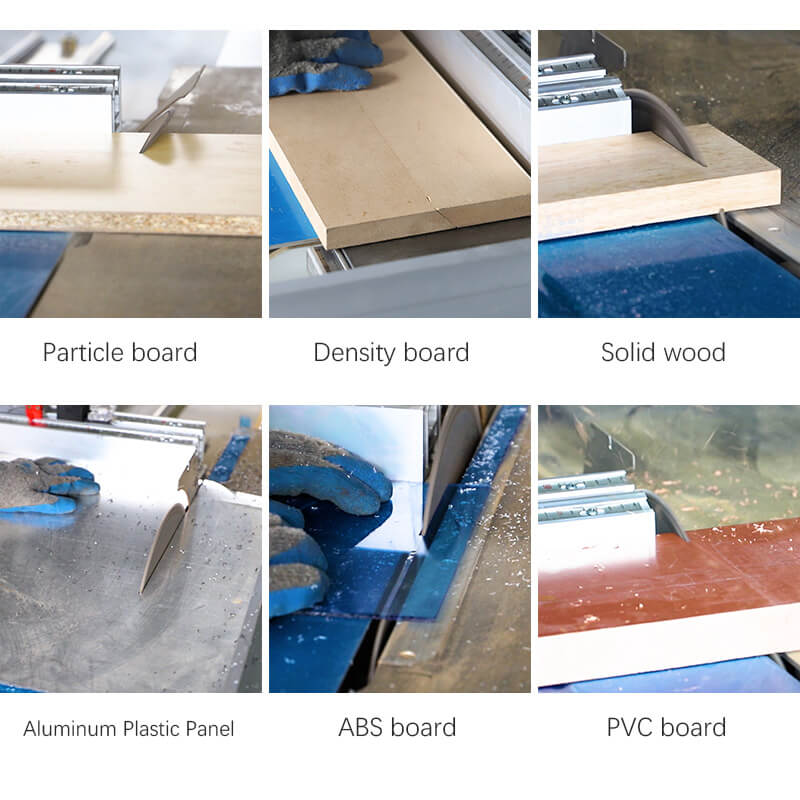

Panel saw machine is a type of woodworking equipment designed for cutting large panels and sheets of wood, plastic, and other similar materials with precision and efficiency. Panel saws are commonly used in woodworking shops, furniture manufacturing, cabinet making, and other industries where accurate and straight cuts in large sheets of material are required.

- This machine tool can provide vertical and horizontal sawing of square lumber and panels, and is suitable for processing various panels such as construction, furniture, vehicle and ship manufacturing.

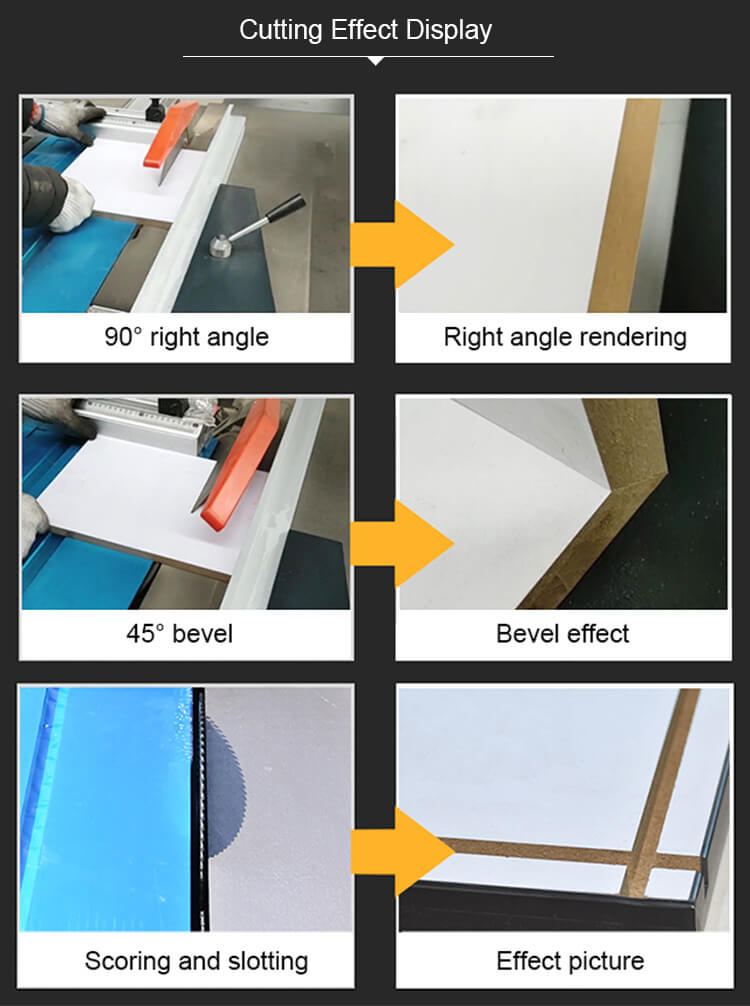

- Features: This machine can saw wood, veneer particleboard, various man-made boards, plastic boards, and aluminum alloy boards. There are two saw blades at the front and back. The front is the pre-cutting saw and the back is the main saw. The two saw blades work at the same time, no planing process after sawing, good smoothness, high accuracy, and no burrs.

- The body has a sliding table and a fixed table. Therefore, the machine can be used for sawing and cutting the sheet size without laying a foundation.

Panel Saw Application

- Cabinet Making: Panel saws are commonly used in cabinet shops to cut sheets of plywood or MDF for cabinet components.

- Furniture Manufacturing: Furniture manufacturers use panel saws to cut large panels for tables, dressers, and other furniture pieces.

- Architectural Millwork: For producing architectural elements like doors, windows, and moldings.

- Sign Making: In sign-making shops to cut large panels for signs and displays.

- Construction: In construction projects for cutting sheathing, siding, and other building materials.

Sliding Table Saw Machine Technical Parameter

| Maximum cutting length | 2800/3000/3200mm |

| Maximum cutting width | 1250mm |

| Main saw blade diameter | 250-300mm |

| Vice saw blade diameter | 120mm |

| Main saw blade speed | 4500-6000rpm |

| Vice saw blade speed | 8000rpm |

| Main saw motor power | 4kw |

| Vice saw motor power | 0.75kw |

| Machine size | 3050*3150*900mm |

| Weight | 800kg |

Types of Panel Saws:

- Vertical Panel Saw: This type of panel saw is designed to make vertical cuts in large panels. It typically has a vertical cutting blade mounted on a carriage that moves along vertical tracks. Vertical panel saws are well-suited for cutting large sheets of plywood, MDF, and other materials into smaller pieces.

- Horizontal Panel Saw: Horizontal panel saws are used for making horizontal cuts in large panels. They have a horizontal cutting blade that moves along a horizontal axis. These machines are often used for cutting sheets into strips or for trimming the edges of panels.

Working principle:

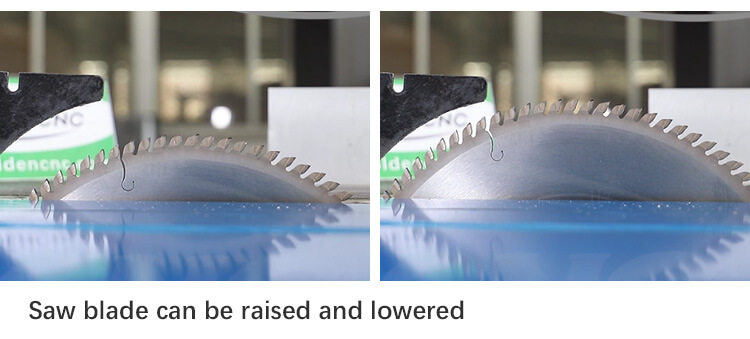

After the adjustment of the machine tool is completed, according to the required plate size, align the backing plate according to the standard size on the worktable. The backing plate can be adjusted horizontally and diagonally. Adjust the main saw blade to an appropriate height (the pre-cutting saw lifting is controlled by the star handle) and then put the plate on the worktable and press the button to realize the cutting.

Maintenance and repair of machine tools

- The cutting and sawdust at the bottom of the machine must be cleaned regularly, especially the track and drive pulley should be kept clean.

- The commonly used adjustment, locking, bolts should be washed and cleaned with resin frequently, and coated with lubricating oil.

- In order to ensure that the sawing does not stick to the guide rail of the double roller carriage, it should be blown with compressed air before leaving get off work every day.

- When the telescopic part of the revolving arm is accumulated with oil, it should be removed and wiped or cleaned with compressed air without dismantling it.

- The bearing of the saw blade shaft is fully enclosed, and it will be replaced after 4000 hours of construction use.

- If any abnormality is found in the use of the machine tool, repair it in time, and pay attention to the location of the original parts and the transmission interval during maintenance.

- If the spindle rotates abnormally or the shaft seat is heated, remove the bearing for inspection. If there is no damage, clean it and inject new oil.

Panel Saw Machine

The horizontal panel saw machine is mainly for cutting various wooden panels and sheets. It takes more space but easier to use than vertical ones. The panel sizing machine mainly includes the computer beam saw (computer CNC panel saw) and the sliding table saw.

Our computer beam saw, also know as panel dividing saw or panel sizing saw, can cut wooden panels with a thickness up to 100mm and the length up to 3700mm with high speed and excellent accuracy. The computer beam saw is the most effective method of precise panel cutting with modern software that allows the saw to gain maximum yields from the materials. Sliding table saw makes cutting tasks easier and safer. It can cut panels at certain angles (22.5°, 45°, 90°) and can also make right-angle and inclined grooves.

If you are looking for sliding table saws, computer controlled horizontal wood saws, panel saws, beam saws, panel sizing centers or an alternatives of vertical panel saws, please read on our site or come to us for latest prices and more details, suggestions.

Features of a sliding table saw

- Humanized design. The panel saw machine adopts a humanized design, and its sliding table adopts a widened design. This makes the wood sawing operation quite easy and labor-saving. It ensures a quick, accurate, and smooth cutting process.

- Pure copper motor. The panel table saw adopts a high-quality panel saw kit. For example, the pure copper motor is powerful and can effectively increase the sawing speed.

- Stable machine bed structure. The machine bed structure of the panel saw machine is made of fine steel. It has the characteristics of high precision, wear resistance, and corrosion resistance, making the fuselage relatively firm.

- Intelligent processing function. From the overall point of view, the sliding panel saw machine adopts a retractable design, and the body can be retracted according to actual production needs. It can be enlarged or reduced at will to adapt to the processed workpieces.

- High processing precision. The panel saw machine adopts an imported round bar guide rail and other high-accuracy and best panel saw kit. All these can effectively improve the sawing accuracy of the equipment.

- Wide range of applications. sliding table panel saw has wide applications in lumber mills, furniture factories, board factories, and other occasions.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.