Wood products are made of wood as raw materials, which are manufactured by mechanical processing. With the improvement of people’s aesthetic level, more and more beautiful and chic wood products are widely loved by consumers, which also promotes the vigorous development of the wood products’ industry.

CNC Router is the perfect computer-controlled machine for cutting and engraving wood, acrylic, MDF, plastic, marble, rubber, epoxy resin, glass, foam, crystal and other materials. It typically falls into two types, ball screw-driven and rack & pinion-driven. More configuration options include carousel or linear ATC, double platforms, auto loading & unloading platforms, auto labeling platform, drilling head, etc.

We all know that traditional wood products need to be hand-carved, which takes a long time and effort, and requires processors to have high requirements such as superb craftsmanship and artistic sense, so the development of the wood product industry is particularly slow. With the advent of CNC machines such as woodworking engraving machines and laser engraving machines, the wood products’ industry has developed rapidly. Whether it is woodworking engraving machine or laser engraving equipment, which all adopt CNC technology, and they have the advantages of high processing accuracy, good processing quality and high processing efficiency, so they are widely used in the wood products’ industry.

iGOLDENCNC will offer you 2022 top rated wood CNC router machines with custom CNC wood cutting, carving, engraving, milling, and routing service to fit your 2D, 2.5D, and 3D CNC woodworking projects, plans, and ideas in wood arts & crafts, sign making, cabinet making, door making, home & office furniture making, decorations, and music instruments.

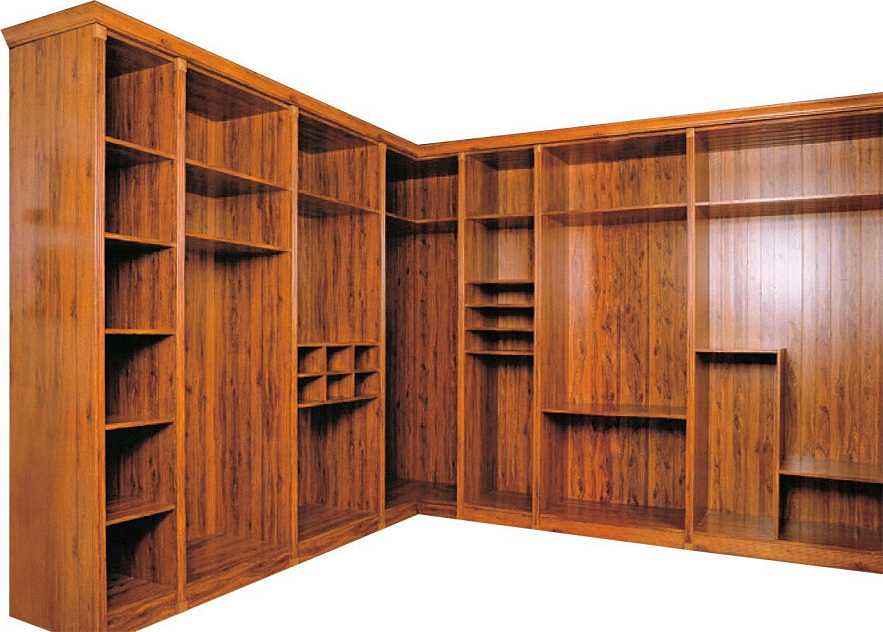

Application pictures of the Wood products industry

Wood products mainly cover furniture wood products, office wood products, craft wood products, garden wood products, living wood products, packaging wood products and other major fields. The processing of the CNC engraving machine covers no matter what field it is, the engraving machine can easily achieve the ideal processing effect. In addition, the application of the engraving machine in the wooden industrial products’ industry can also be reflected in the production of sewing machine counter tops, electrical cabinet panels, sports equipment and so on.

Why choose our CNC router machine?

Customized production can save you 30% of additional procurement costs. We can customize the wood CNC machine in accordance with your specific CNC wood carving demands. The custom options may include the worktable size, worktable type, power and brand of all mechanical and electrical parts of the wood CNC machine.

International top brand accessories to ensure your higher productivity and increase profit margin by 40%. All major mechanical and electrical parts of our wood CNC machine come from domestically or internationally known brand. For example, HSD spindle, YASKAWA motor, SIEMENS control system, etc.

Professional product and operational training, reducing operating error rate by 80%. We have a R&D team of more than 20 people focusing on the production and innovation of the wood carving machine. Our 6 sales team of more than 40 people can provide you with complete information of the wood carving machine in time.

Perfect after-sales service can help you avoid any worries in the use of the machine. An after-sales team of over 15 people provides you with 24/7 online and offline services to solve your worries about the CNC wood cutting machine.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.